1.Polishing refers to the use of mechanical, chemical or electrochemical effect, so that the workpiece surface roughness reduction, in order to obtain a bright, smooth surface processing method.Is the use of polishing tools and abrasive particles or other polishing media on the workpiece surface modification processing.Polishing does not improve the dimensional or geometric precision of the workpiece, but to get a smooth surface or mirror gloss for the purpose, and sometimes to eliminate the gloss (extinction).

2.Sand blasting is the process of cleaning and coarsening the substrate surface by means of the impact of high-speed sand flow.Using compressed air as the power, to form a high-speed jet bundle to spray material (copper ore, quartz sand, emery sand, iron ore, hainan) high-speed jet to need to deal with the workpiece surface, make the appearance on the surface of the workpiece surface appearance or shape change, due to the abrasive impact to the surface and the cutting effect, make the surface of the workpiece for cleanliness and different roughness, the workpiece can improve the mechanical properties of the surface, thus improve the fatigue resistance of the workpiece, increase the adhesion between the coating and its, extend the durability of the coating, but also to the flow of paint and decoration.

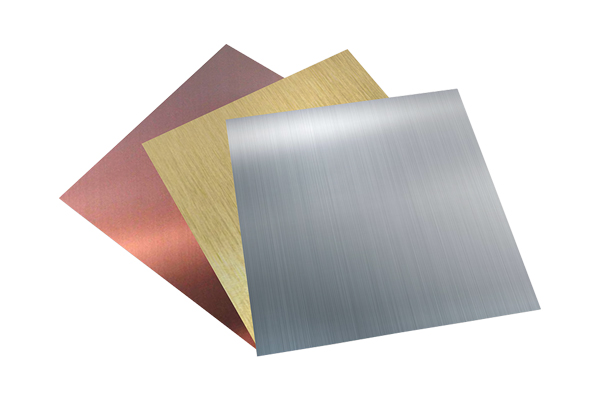

3. Drawing is a surface treatment method that forms lines on the workpiece surface through grinding products and plays a decorative effect.According to the different patterns after drawing can be divided into: straight drawing, random drawing, ripple, spiral.Surface wiredrawing is a kind of surface treatment method that forms lines on the workpiece surface through grinding products and plays a decorative effect.Because the surface drawing processing can reflect the texture of metal materials, so it has been more and more popular and widely used by users.

4.Anodic oxidation an electrolytic oxidation process in which the surfaces of aluminum and aluminum alloys are usually converted into an oxide film with protective, ornamental, and other functional properties.The anodic oxidation of aluminum from this definition includes only the part of the process that produces the anodic oxide film.Metal or alloy parts are used as anodes, and oxide films are formed on their surfaces by electrolysis.

5.Electrophoresis is divided into anode electrophoresis and cathode electrophoresis.If coating particles are negatively charged, the workpiece is an anode, and coating particles are deposited into a film on the workpiece under the action of electric field force, which is called anodic electrophoresis.On the contrary, if coating particles with positive charge, the workpiece for the cathode, coating particles on the workpiece deposition into a film called cathode electrophoresis.

6. PVD is English Physical Vapor Deposition (PVD) abbreviation, is refers to under the condition of vacuum, with low voltage, high current arc discharge technology, by use of gas discharge from target material evaporation and evaporation occurs matter and gas ionization, using electric field acceleration, cause the evaporation material and the reaction product Deposition on the workpiece.Physical vapor deposition process is simple, environmental improvement, no pollution, less consumable materials, uniform film density, strong adhesion with the matrix.The technology is widely used in aerospace, electronics, optics, machinery, construction, light industry, metallurgy, materials and other fields, can be prepared with wear-resistant, corrosion resistant decoration, electrical, insulation, optical conductivity, piezoelectric, magnetic, lubrication, superconductivity and other characteristics of the film.

7. Electroplating (Electroplating) is the use of electrolytic principle in some metal on the surface of a thin layer of other metal or alloy plating process, is the use of electrolytic action made of metal or other materials adhered on the surface of the parts of a layer of metal film technique to prevent metal oxidation (rust), improve the wear resistance and electric conductivity, reflective resistance, corrosion resistance, copper sulfate, etc.) and create beautiful etc.Many COINS are also plated.

8.Etching is usually referred to as etching, also known as photochemical etching, refers to the process of exposure plate making, development, will be etched area of the protective film removal, contact with the chemical solution during etching, corrosion dissolution, forming a concave or convex or hollowing effect.Details can be learned at guangzhaolong stainless steel factory.

More color stainless steel processing technology, please visit: https://www.meibaotai.com

Post time: Jan-24-2019