For color stainless steel plate factory, produce the products with quality guarantee, is their own responsibility, but in front of interests, often a lot of accurate color stainless steel plate manufacturers will not be able to balance interests between quality and weight, as a result, color stainless steel plate factory to bring us how important points at the time of purchase, to avoid purchasing to the quality defective color stainless steel plate:

I. material discrimination:

The common materials of color stainless steel plate are 304, 201 and 201 calendering materials.Among them, 304 has higher corrosion resistance than 201, and the normal material is smoother and brighter than the calendering material.Because the price difference is big, many color stainless steel plate manufacturers shoddy, with calendering materials posing as materials, posing as 304 with 201.As a result, the colored stainless steel plates began to fade, rust and even break after a few months.Therefore, the inspection of the first thing to do is to verify that the material is your designated plate.201 and 304 can be used to detect potion resolution, while is material and rolling material mainly by looking at the quality of the panel to distinguish, the material is uniform plate surface smooth smooth, colour and lustre, high brightness, the whole plate, thickness, and rolling material board face slants dark, uneven color, often with black or stripes, the back roller embossing, sand holes, peeling defects such as water mark, the thickness of the plate is poor can reach 2 to 3 C (1 C = 0.01 mm).But as a lot of manufacturer of chromatic stainless steel plate produce craft and technical rise, the gap of material and calender is being narrowed slowly, some copy is material board, can distinguish with false even true, need has the professional personnel with rich experience ability to distinguish.

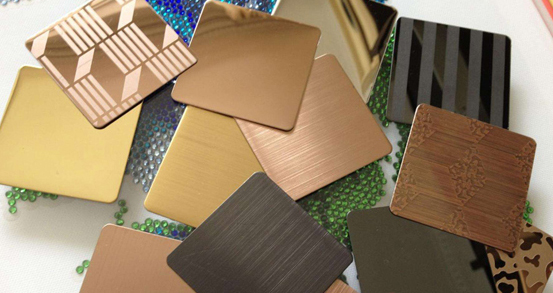

Ii. Appearance:

The color stainless steel plate is mainly used in the decoration field.When inspecting goods, be sure to examine and observe carefully.Good color stainless steel plate in direct sunlight should be no visual discoloration, the whole batch of plate without color.Color uniform, good color, no scratches bend not fade.The surface of the mirror should be no grinding head flowers and horseshoe prints, high brightness.Of course, normally the board with better quality, the price is more also, to the requirement not tall adornment domain also can reduce to the requirement of board face, the choice is more economy more substantial adornment board.

Iii. Key points of procurement

The current coloring technology of colors such as emerald green and amaranthus is not very mature. The colors of different batches of boards may have obvious color differences. Therefore, before purchasing, it is necessary to budget the quantity and size to be purchased and buy enough quantity at one time.Even if it is titanium plate, rose gold plate, black titanium plate and other common color stainless steel plate is also recommended to purchase enough, after all, the more the number, the more affordable price from the manufacturer.But if it is with strange, not familiar with the manufacturer cooperation, before large quantities of procurement, it is recommended that you first purchase dozens of small batches of boards to examine the quality and effect.Although, many color stainless steel plate manufacturers will provide samples for customer reference.But actually a piece of palm is big with this the action that does not see quality stand or fall, can rise to compare color or design only.

Iv. Tear laminating:

Color stainless steel plate factory will be affixed with a protective film.A lot of unsalable plank, put aside long in storehouse time, protective film changed powder, tear very hard, or after tearing, plank surface still is sticking a lot of glue, namely ugly clear hard, take time and labor.Even if it is transparent film, everyone in the inspection, also must tear a large piece to see the quality of the film.If the need for subsequent shear bending molding, it is best to put more than 6C protective film, to avoid scratching the board.Color stainless steel plate after installation, should be torn off the film as soon as possible, with glue.Especially outdoor decoration, because of direct sunlight, after the construction had better immediately tear off the protective film.

More color stainless steel plate information, please visit: https://www.meibaotai.com

Post time: Apr-22-2019