The surface of the film coated production line is very smooth, just like what we see in our daily life, but many friends will not think it is with its own?In fact, this is also into the artificial processing, this is what we say the aesthetic degree, appearance of clean, give a person’s feeling is very new, so how to improve the laminated stainless steel sheet production line surface clean degree?

There are cold method and hot hair two coating technology: cold method with ethanol resin solution, and in the sand mixing process to add ulotropin, the two coated on the surface of sand, ethanol volatilization, coated sand;Heat method to preheat the sand to a certain temperature, add resin to make it melt, stir the resin coated in the surface of sand, add ulotropin aqueous solution and lubricant, cooling, crushing, screening share coated sand.Used for casting steel and cast iron.

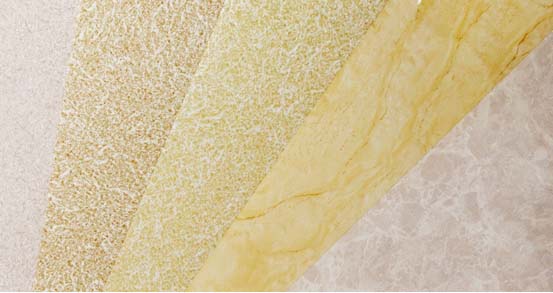

Coated sand cast steel finish: mainly and coated sand high temperature resistance is poor, can add some high temperature resistance additive, this additive at high temperature solid phase sintering to make the casting smooth, the surface of sand is covered with a layer of solid resin film sand or core sand.

Coated sand industry standards in the coated sand must test indicators: room temperature bending strength, thermal bending strength, burning reduction, particle size and melting point.Optional testing indicators are: normal temperature tensile strength, hot tensile strength, gas generation and fluidity.

In recent 10 years, the performance of coated sand has been greatly improved, and some new indicators have been added:

(1) heat resistance time — test the time when the coated sand core maintains strength, no deformation and no collapse at high temperature (700-1500℃).

(2) anti-shucking ability — test the anti-shucking ability of coated sand.

(3) high temperature compressive strength of coated sand — simulate the actual conditions of casting and test the compressive strength of coated sand core at 1000-1500℃.

More laminated stainless steel sheet information please visit: https://www.meibaotai.com

Post time: Jun-27-2019