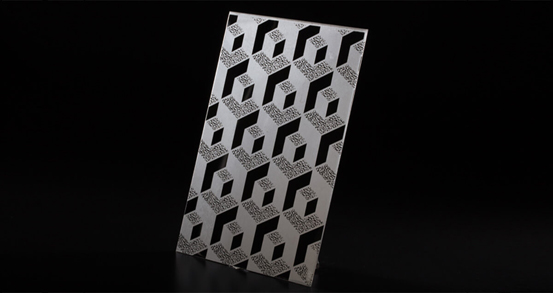

Principle of etched stainless steel plate:

With the strong oxidation of ferric chloride, the surface of stainless steel is corroded and ferric trivalent elements become more stable iron elements.The specific production technology is coating the surface of stainless steel anti-corrosion layer, protection should protect the part, put into the production line spraying ferric chloride, corrosion after the end of the anti-corrosion layer washed off, form a pattern.

The etched process is as follows:

1. Etching pre-treatment is an important process to ensure the tightness between screen printing and metal surface, so the grease and oxidation film on the metal etching surface must be completely removed.

2. Oil removal is proposed according to the oil pollution of the workpiece. Before screen printing, electrolytic oil removal is carried out to ensure the effect of oil removal.

3. In order to remove the oxide film, a good etching solution must be selected according to the type of metal and film thickness to clean the surface.

More information about etched stainless steel plates can be found at: https://www.meibaotai.com

4, screen printing must be dried before.Moisture can also affect the ink’s adhesion, and later the etchings collapse, affecting the decorative effect.

5, screen printing must be based on the needs of printing, the production of standard pattern screen.In the decorative process of patterns, screen printing mainly play a protective role, coating photoresist, because the production of thick screen template, good masking performance, etched patterns of high distinctiveness.

6, screen version of the film under the action of light photochemical reaction, light irradiation part set up in water insoluble film, light irradiation part dissolved in water, screen space exposed, coated with film screen version printed in accordance with the black and white positive screen pattern.

Post time: Sep-16-2019