Stainless steel decorative plate drawing process: in the process of metal pressure, driven by external forces, stainless steel through the exclusive mold, so that its cross-sectional area is compressed, and the required shape and size of the technical processing method for the wire drawing process.

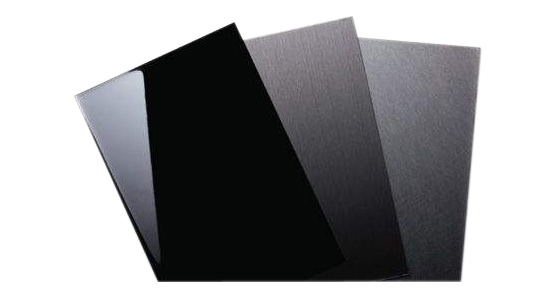

The effects of wire drawing process are generally straight lines, random lines, ripples, swirl lines and so on.

The formation of straight wire drawing is in the stainless steel surface with mechanical friction method to produce straight lines, which is the most simple and rough wire drawing process.

Random drawing is in the high-speed operation of the drawing die, so that the stainless steel around the front and rear movement of friction and the formation of a non-regular, no obvious lines of the drawing.

Ripple is generally made in the brush or brush machine, using the axial movement of the upper group of grinding rollers, grinding brush on the metal surface, get wavy lines.

Spiral, also known as optical rotation, mainly with cylindrical felt or grindstone nylon wheel drilling machine, with kerosene and polishing cream, the metal surface of the rotary polishing and forming a drawing silk.

Even after the wire drawing process of stainless steel, no matter which a grain, there is a common defect, that is, monochromatic;Can only change the shape, size of stainless steel, the drawing technology does not change its original silver grey color, so the plating process is more important, we can through the wire drawing process combined with plating process, there was no this defect, and improve the appearance at the same time, also can enhance the service life of the stainless steel corrosion resistant ability, etc.

More stainless steel decorative plate drawing process, please visit: https://www.meibaotai.com

Post time: May-11-2019